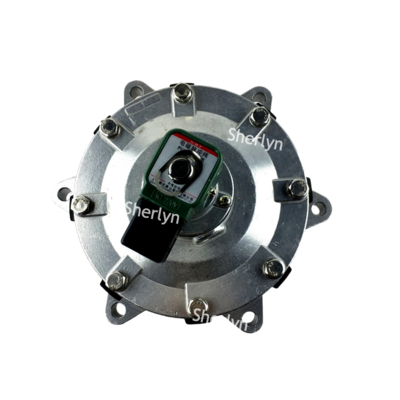

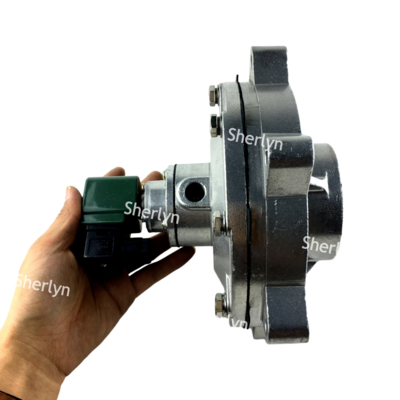

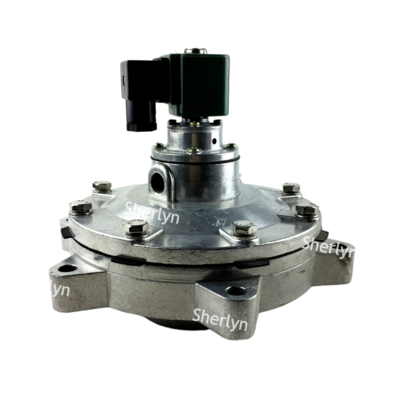

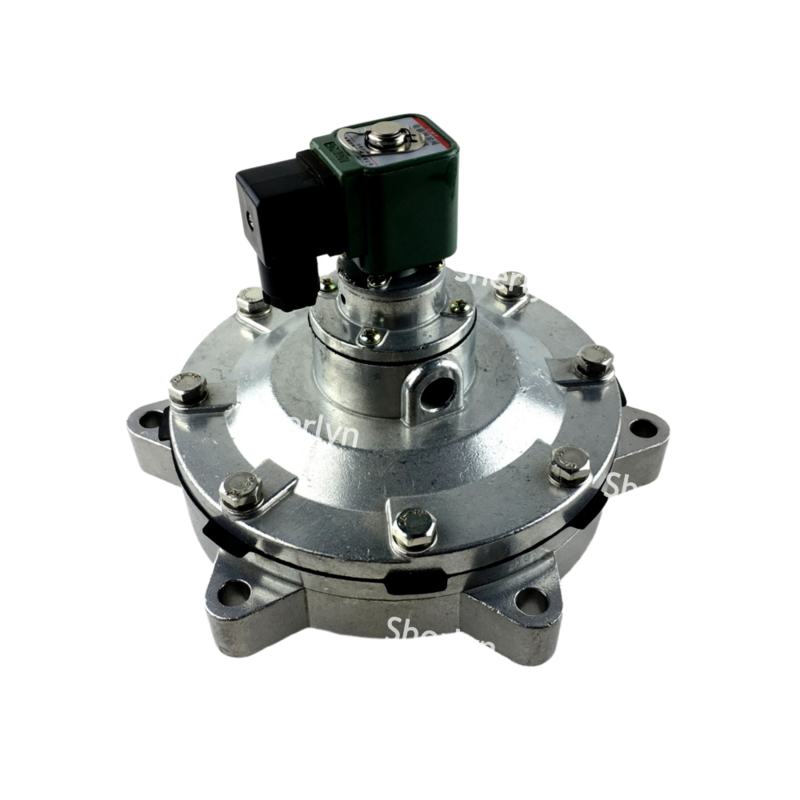

Wbudowany zawór membranowy DMF-Y-62S 2-1/2'' cala do odpylacza z podwójną membraną

Główny typ zaworu impulsowego do worków filtracyjnych typu SBFEC::

1. Zawór kątowy

Ten rodzaj zaworu impulsowego z kątem 90° pomiędzy wlotem i wylotem. Upraszcza połączenie pomiędzy workiem gazowym a rurą nadmuchową odpylacza. Może zapewnić silniejszy przepływ powietrza i spełniać wymagania dotyczące usuwania pyłu. Podobnie jak zawór impulsowy serii DMF-Z.

2. Zawór zanurzeniowy

Ten rodzaj zaworu impulsowego jest instalowany bezpośrednio na wtórnym worku gazowym i zapewnia lepszą jakość cyrkulacji. Zawór ma mniejsze straty ciśnienia i ma zastosowanie do operacji z niższym ciśnieniem gazu. Podobnie jak zawór impulsowy serii DMF-Y.

3. Zawór z nakrętką kołnierzową

Ten rodzaj zaworu impulsowego jest podobny do zaworów serii z, odpowiedni do połączenia pomiędzy workiem gazowym a rurą nadmuchową odpylacza. Posiada stałe nakrętki do celów instalacyjnych na wlocie i wylocie, co ułatwia instalację i zastosowanie. Podobnie jak zawór impulsowy serii DMF-ZM.

4. Zawór przelotowy

Ten rodzaj zaworu impulsowego z kątem 180° pomiędzy wlotem i wylotem (linia środkowa zarówno wlotu, jak i wylotu jest tą samą linią prostą). Ponadto wlot jest połączony ze zbiornikiem gazu, a wylot z rurą nadmuchową. Podobnie jak zawór impulsowy serii DMF-T.

Wszystkie rodzaje zaworów impulsowych w magazynie. Zapraszamy do zapytania.

Zastosowania:

Przemysłowy system usuwania pyłu

Metalurgia żelaza i stali: Stosowany do środowisk o wysokiej temperaturze i dużym zapyleniu, takich jak głowice spiekania i oczyszczanie gazu wielkiego pieca, wymagających użycia chłodnicy (temperatura ≤ 60 ℃). Zaleca się stosowanie zaworu kątowego DMF-Z lub zaworu zanurzeniowego.

Produkcja cementu: Odsysacz pyłu z wylotu pieca, usuwanie pyłu z mielenia surowców, kompatybilny z zaworem zanurzeniowym DMF-Y (np. DMF-Y-80), odporny na pył w temperaturze otoczenia (<80 ℃).

Spalanie odpadów: Do obróbki kwaśnych spalin wymagane są zawory zanurzeniowe z gumy fluorowej (FKM) (np. DMF-Y-62S), co może zwiększyć odporność na korozję 8-krotnie.

Przetwórstwo drewna/przemysł chemiczny spożywczy: Scenariusze pneumatycznego transportu trocin lub proszku, odpowiednie do zaworów przelotowych (seria DMF-T), wymagające suchego powietrza bezolejowego (zawartość oleju<5ppm).

System pomocniczy

Przełamywanie łuku w bunkrze: Most materiałowy w silosie na pył węglowy i silosie na ziarno jest przełamywany przez impulsowy przepływ powietrza, z częstotliwością ≤ 30 razy/min.

Usuwanie blokad w transporcie pneumatycznym: Zainstaluj zawory impulsowe w punktach blokady rurociągu, aby natychmiast rozpylać i usuwać materiały proszkowe (takie jak granulki z tworzyw sztucznych i węglan wapnia spożywczy).

Dane techniczne zaworu impulsowego zanurzeniowego serii DMF typu BFEC:

| Zawór gwintowany |

3/4'' |

1'' |

1.5'' |

2'' |

2.5'' |

3'' |

4'' |

| DMF-Z-20 |

DMF-Z-25 |

DMF-Z-40S |

DMF-Z-50S |

DMF-Z-62S |

DMF-Z-76S |

DMF-Z-102S |

| Zawór do szybkiego montażu |

3/4'' |

Wlot φ27 |

1'' |

1.5'' |

| DMF-ZM-20 |

DMF-ZL-B |

DMF-ZM-25 |

DMF-ZM-40S |

| Zawór kołnierzowy |

1'' |

1.5'' |

| DMF-ZF-25 |

DMF-ZF-40S |

| Zawór wbudowany |

1'' |

1.5'' |

Wylot φ62mm |

Wylot φ75 |

Wylot φ89 |

Wylot φ114 |

Wylot φ102 |

| DMF-Y-25 |

DMF-Y-40S |

DMF-Y-50S |

DMF-Y-62S |

DMF-Y-76S |

DMF-Y-102S |

DMF-Y-102SA |

|

|

|

|

|

|

|

|

Wsparcie i usługi:

Nasz zespół wsparcia technicznego dla zaworów impulsowych jest dedykowany zapewnianiu pomocy w przypadku wszelkich pytań technicznych lub problemów, które możesz napotkać. Nasz zespół ekspertów jest dostępny, aby pomóc w rozwiązywaniu problemów, diagnozowaniu i rozwiązywaniu wszelkich problemów technicznych w celu zapewnienia optymalnej wydajności Twoich zaworów impulsowych.

Oprócz wsparcia technicznego oferujemy również szereg usług dla zaworów impulsowych, w tym konserwację, naprawy i wsparcie instalacyjne. Nasz zespół może zapewnić wskazówki dotyczące prawidłowych procedur konserwacji, technik rozwiązywania problemów i najlepszych praktyk w celu zapewnienia trwałości i wydajności Twoich zaworów impulsowych.

Niezależnie od tego, czy masz pytania dotyczące instalacji, rozwiązywania problemów, konserwacji czy jakiegokolwiek innego aspektu technicznego Twoich zaworów impulsowych, nasz zespół wsparcia technicznego jest tutaj, aby pomóc w zapewnieniu potrzebnej pomocy.

Pakowanie i wysyłka:

Opakowanie produktu:

Zawory impulsowe są starannie pakowane w solidne kartony, aby zapewnić bezpieczny transport i dostawę. Każdy zawór jest bezpiecznie amortyzowany wkładkami z pianki, aby zapobiec uszkodzeniom podczas wysyłki. Opakowanie zawiera również wyraźne etykiety ułatwiające identyfikację produktu.

Wysyłka:

Zamówienia na zawory impulsowe są zazwyczaj przetwarzane w ciągu 1-2 dni roboczych. Oferujemy różne opcje wysyłki, w tym standardową wysyłkę lądową, wysyłkę ekspresową i wysyłkę międzynarodową. Klienci mogą śledzić swoje zamówienia za pomocą podanego numeru śledzenia, aby monitorować status dostawy. Dokładamy wszelkich starań, aby zapewnić szybkie i niezawodne usługi wysyłkowe wszystkim naszym klientom.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!